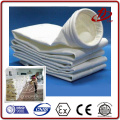

Dust Collector Bag /Dust Filter Bag/Air Filter Bag

Product Description

Dust Collector Bag /Dust Filter Bag/Air Filter Bag

1. long work life

2. High dust collection efficiency

3. Many types of material can suit for many industry and dedusting cases

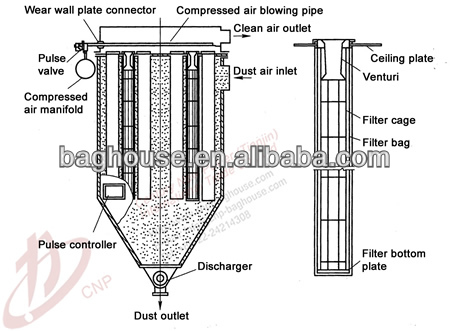

INTRODUCTION

Filter bag is the core of the dust filter components. The filter bag has the strict requirements on design, filter material cutting, woven technology etc. These requirements are very important for the normal operation of the bag filter and convenient maintenance, and it is great significance to enlong the service life of the filter bag.

Structure and application

Filter bag are composed by woven filter material bag body and supported in role, snap ring, clamp, chain hoist, etc. The rest of the filter bag Dust Collector and its accessories are the venturi tube, frame, mouth of elastic ring, etc.

Specifications

The diameter of the filter bag is 115-200mm, length is 2000 - 9000mm, the specifications of the commonly used filter bag is 120 - 160 mm diameter, 2000 ~ 6000mm length.

Filter bag processing need attention

Filter bag processing matters that should be paid attention:

After the selection of filter bag material and determine the specifications of the filter bag, we will process the filter bag as following attention matters:

(1) Precise design required size of the filter cloth for filter bag parts, the filter cloth will larger than the actual amount design size, to leave a spare for weaving.

(2) To choose the right filter bag accessories, specifications and check its quality. The filter bag accessories should match the filter bag quality requirements.

(3) We make the filter bag line drawing, cutting, sewing on automatic production line. When the filter bag need manual processing, we will open it on the operation platform, and with certain pulling force to keep it is flat.

(4) We keep the strict processing quality standards, according to design drawings and operation process. Our worker meet the requirements of tooling and clothing shoes and hats, no smoking.

Filter bag should be according to the design requirements for inspection and repair after sewing, eliminate surface crease, dirt and grease. For PTFE coated filter bag, in addition to the needle density control and strict operating procedures, it needs to use special materials for all the pin hole repairing.

Filter bag manufacture should be according to the national standards, industry standards and enterprise standards, quality supervision departments according to the number of sampling test project and the proportion. According to the number of sampling ratio is 5% ~ 20%. For higher requirements on the filter bag, As a group of sampling rate should be above 15%.

Dust collector's lung High temperature cement industry dust collection waterproof filter bag

Working occasions

In industry dust collection

Power Stations

Filtered dust

Flue ash, discharging flue ash

Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals,

Pure clay, phosphates, magnesite concentrate, finely ground

fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer)

Rubber compounds, sinter dust, catalysts

Sodium sulfate

Soap powder

In machinery top:

Silos / Tanks

Discharging systems

Warehouse units

Mixing equipment

Homogenizing systems

Chute Bottoms

Conveyor systems

Ventilator systems

Aeration systems

Powder Coating Machinery

Bottoms for sinter basin

Dust Filter bag for High temperature cement industry dust collection waterproof application

********************

Please click the following product name to view more product details:

SINGLE BAG FILTER ROUND PULSE FILTER Centrifugal Fan REVERSE BLOW FILTER DUST COLLECTOR

FILTER BAG / FILTER CAGE Screw Conveyor Airslide Fabric / HOSE PULSE VALVE UNLOADER FILTER FELT

********************

Product Categories : Dust Respirator

Premium Related Products