Stainless steel auger feeder

Product Description

Secure Payment service support !! We are Trade Assurance supplier! Order us from your alibaba account directly.

Introduction

Screw Conveyor is a kind of continuous transmission equipment which without immunity traction components, it uses rotation screw to convey material. The screw conveyor is of simple structure, low marking cost, strong sealing, safe ,convenient operation and other advantages, It allows multiple inlets and outlets. It is widely used in various industrial department(such as building materials, chemicals, electric power, metallurgy, coal, mine, food and other industries)to convey powder, granular and lump material, such as, coal, ash, slag, cement, food, etc. The temperature of material is less than 200°C. Screw conveyor is not suitable for transporting those material which is perishable, with big viscous and easy caking. In the concrete mixing plant screw conveyor's effect reflected to the fullest.

Application:

Loose materials such as powder, granular and small piece material , which includes: clay powder, pulverized coal, coffee bean, sand, grain, cherry , cobble, and cast iron filings, ice, etc.

It is widely used for the grain transportation and some corrosion resistance of the material.

Some detail parts:

Working principle

Screw conveyor is relying on a spiral blade shaft in the trough of closed continuous rotation in order to impel the lose of material moving. At this time, the material are like the bolt, in spinning along the axial moving forward gradually, finally discharging mouth off.

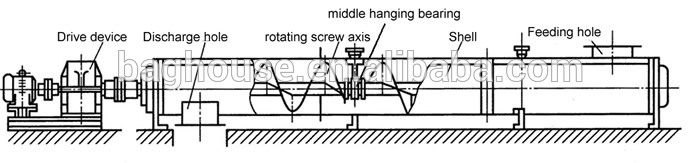

Screw conveyor Structure

The structure of the screw conveyor, mainly by the drive device, discharge hole, rotating screw axis, bearings, housing and feeding port, etc. Usually screw conveyor has the bearing on the material movement terminal side, it can withstand the material to spiral axial force of the blade. When the conveyor is longer than the fuselage, it should be added the middle hanging bearing.

Characteristic

1. Efficient delivery : small diameter , high rotating speed, large transmission capacity, variable pitch of spiral body, and small resistance of intermediate bearing make loading material smoothly, quickly and evenly.

2. Random arrangement : conveyor has good integral rigidity and can transport the products flatly or steeply inclined, it can be connected with its corollary equipments directly , and can be set up and dismantled easily with small floor space.

3. Good lubrication : low oil lubricating sliding tile, multilayer labyrinth oil seal design and integral lubricating system composed of of oil pump, distributor and pipeline are convenient and can completely lubricate all the running parts.

4. Reliable sealing : the dust cover of reducer is reliable for preventing leakage which can protect reducer and create good working condition. Improved peephole can prevent water seepage and material leakage.

5. Diverse connection : feed inlet and outlet can be connected not only with universal ball, bag,flange etc but also butterfly valve and gate valve.

6. Innovative design: special reducer designed and produced with introduced technology not only has the advantages of a small size, a big bearing torque.

Technical Parameters

ing material handling machine bulk cement feeder the spiral screw conveyor

********************

Please click the following product name to view more details:

SINGLE BAG FILTER ROUND PULSE FILTER Centrifugal Fan REVERSE BLOW FILTER Dust Collector

Filter Bag / FILTER CAGE SCREW CONVEYOR Airslide Fabric / HOSE PULSE VALVE UNLOADER FILTER FELT

f application

1. Enquiries quickly reply within 24 hours.

2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved.

3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design.

4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle.

5. The bag filter equipment over 20 years working life.

6. Associated with equipment spare parts, ensure the replacement parts within 20 years.

7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production.

8. Ensure easy operation and absolutely no worries about future.

Contact us if you need more details on Auger Feeder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Auger Feeder for Pet Flakes、Stainless Steel Auger Feeder. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Filter Spare Parts > Screw Conveyor

Premium Related Products